Manufacturing’s Top Challenges and How CPQ Solves Them

A common question we get is What Challenges can CPQ Solve? For sales, it's easier than ever to create a customer centric buying journey

What Challenges can CPQ Solve?

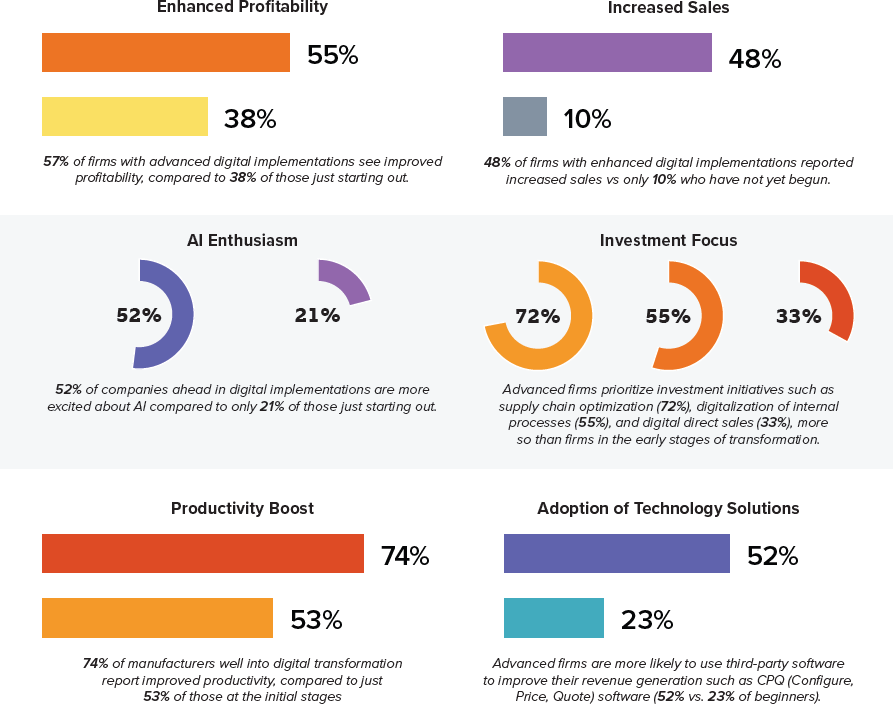

Precision, efficiency and profitability are all signs of a healthy manufacturing organization, but achieving these goals is a challenge for many businesses. Manufacturing executives face an array of challenges in their quest to hit these goals.

From an unpredictable supply chain, a changing buyer demographic and sustainability initiatives, the manufacturing sector demands adaptability and innovation. However, amidst these demands, several pain points consistently emerge for manufacturing executives, hindering their ability to thrive in an increasingly competitive market.

Understanding the Pain Points:

1. Process Efficiency:

Product complexity and customer demands have made the process of configuring, pricing and quoting products for manufacturers a huge challenge. These inefficiencies are caused by time-consuming, manual processes that are used to create quotes for customers.

Finding ways to cut down on the time required to create quotes will be a major success factor for new solutions. Streamlining these processes is crucial for enhancing efficiency and reducing manual and time-intensive administrative tasks.

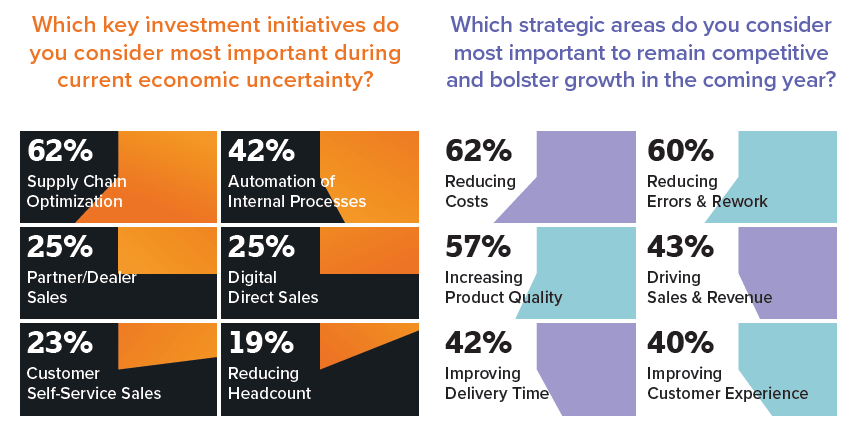

2. Cost Reduction and Margin Improvement:

Every manufacturing operation is actively pursuing strategies to reduce operational costs and enhance profit margins. This involves empowering sales teams to focus on selling value rather than solely emphasizing functions and features. Additionally, companies aim to minimize expenditures related to maintaining existing systems and mitigate quoting errors to prevent revenue loss.

3. Sales and Customer Experience Transformation:

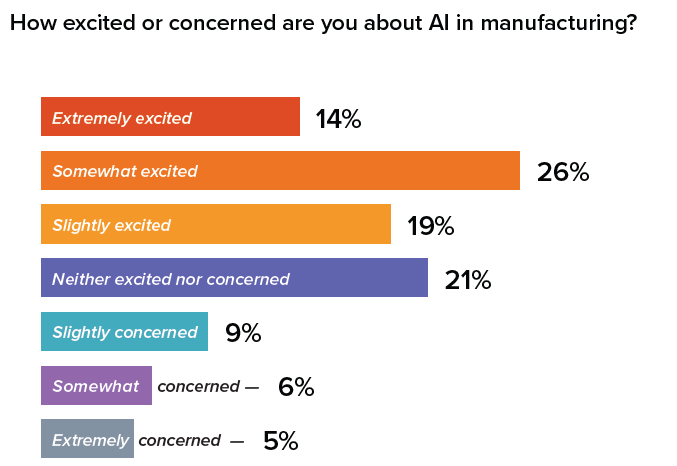

A strong momentum in manufacturing exists towards digital transformation initiatives, encompassing the modernization of sales processes, the adoption of cloud-based solutions to enhance scalability and cost-effectiveness, and the integration of new features aimed at bolstering business support capabilities. But with so many options and different paths executives can take it’s difficult to find a solution that can handle all the challenges faced by a modern manufacturing operation.

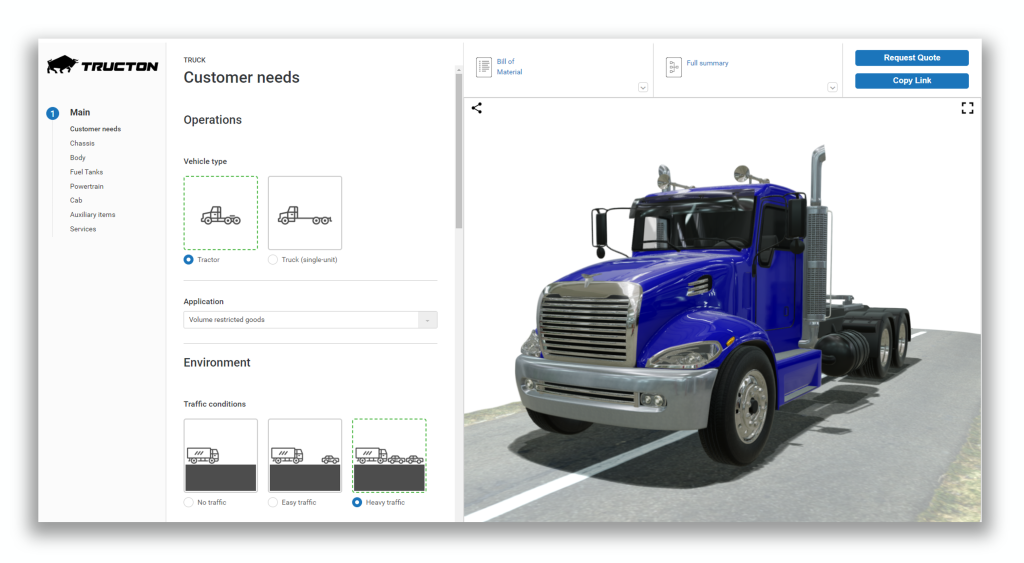

Companies strive to enhance the purchasing journey and sales strategies by refining e-commerce interfaces and user experiences (UX). Manufacturers need to adopt strategies that make it easy to sell their products, while also creating an exciting buying experience for their customers.

Additionally, they seek to empower dealers and sales representatives with shared and holistic solutions enabling them to generate precise dimensional drawings and quotes swiftly.

5. Sales and Technical Brain Drain

Many manufacturers also face staffing issues, retirements and key member departures can lead to brain drain for the organization. In 2023 alone, manufacturers on average saw turnover rates at a staggering 28.6%. Adopting new solutions and automation can enhance operational efficiency, improve product quality, and streamline processes by reducing the reliance on a few critical resources companies use to quote their products.

6. Sales Execution and Customer Experience Analytics:

Companies are seeking to streamline their operations by consolidating various systems and configurations, aiming to achieve a unified perspective of the sales lifecycle. This consolidation not only enhances accountability but also minimizes the time required for generating quotes.

7. Competitiveness and Market Adaptability:

In the face of escalating competition, companies must remain agile and adaptable. Finding a solution that decreases costs, boosts sales efficiency, and enables quick adaptation to market changes, ensuring competitiveness in the long run will be critical to success. Find out

How Tacton Addresses These Trends:

CPQ solutions like Tacton offer a comprehensive suite of features tailored to address the unique pain points of manufacturing executives:

Replicating Your Best Sales Reps and Solution Consultants

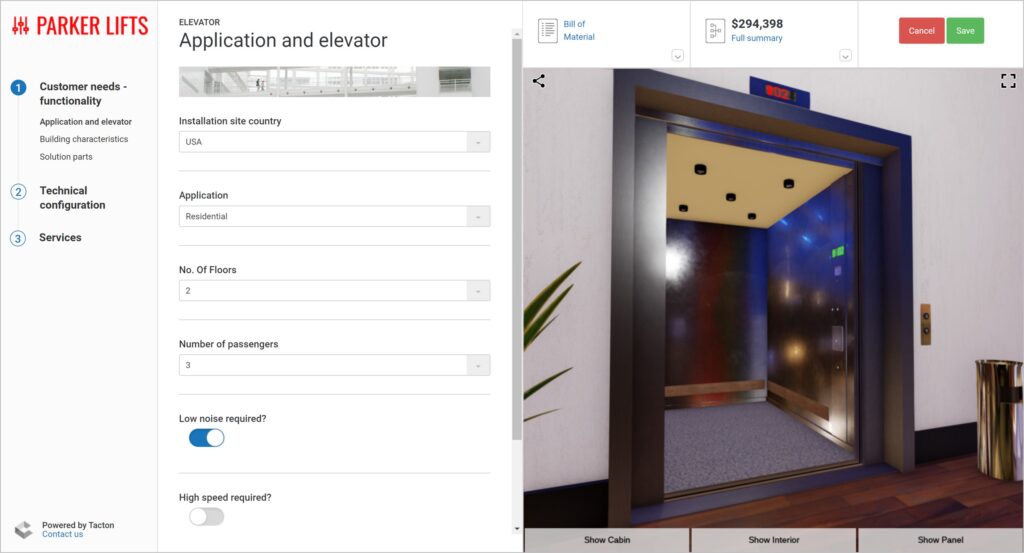

With Tacton’s advanced configuration it’s easier than ever to guide customers and sales reps through the sales process. This ensures that even less experienced sales reps can make accurate and optimal product configurations that meet customer needs, like what an expert would do.

Tacton also dynamically generates prices and quotes based on the selected configurations, this ensures that pricing is always accurate and competitive, a task that many times requires deep product and market knowledge.

Simplifying Product Configuration:

CPQ enables manufacturers to streamline product configuration by providing intuitive tools for managing complex product catalogs. By centralizing product data and automating configuration processes, CPQ minimizes errors and ensures consistency across quotes. Find out how our customer IMI uses Tacton to manage their global portfolio of products with Tacton.

Automating Quoting Processes:

With CPQ, manufacturers can automate the generation of quotes, reducing the time and effort required to produce accurate proposals. By integrating with CRM systems and ERP software, CPQ streamlines workflows and facilitates collaboration between sales and engineering teams.

Dynamic Pricing Optimization:

CPQ offers advanced pricing capabilities, allowing manufacturers to implement dynamic pricing strategies based on real-time market data and customer insights. By leveraging pricing analytics CPQ helps manufacturers maximize profitability while remaining competitive.

Accelerating Sales Cycles:

By streamlining quoting processes and providing sales reps with access to self-service tools and guided selling workflows, CPQ accelerates sales cycles and improves win rates. Our customer Siemens reduced quoting time from 8 days to minutes.

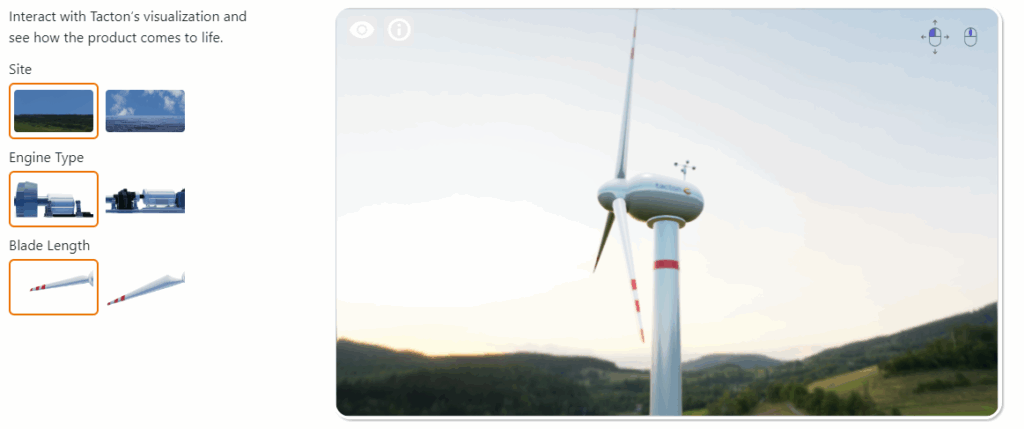

Guided Selling and Visualization:

With features like Guided Selling and 3D Visualization, Tacton enables manufacturers to enhance the sales experience and drive customer engagement through interactive product presentations.

Confidence for the Newest Sales Rep

With the help of CPQ it’s easier than ever to bring your newest sales reps up to speed on the product portfolio. By creating an error-proof and accurate process with CPQ, even new sales reps can build confidence in selling to your prospects.

Customer-Centric Approach:

Tacton’s customer-centric approach ensures end-to-end support, from lead generation to order fulfillment, fostering long-term relationships and customer satisfaction.

Optimize Products Based on Sustainability Requirements:

With Tacton’s Environmental Footprint Configuration it’s easier than ever to integrate with Life-Cycle Assessment tools to empowers your sales rep or end customer to reduce the footprint through product selections to meet their needs and legislative requirements.

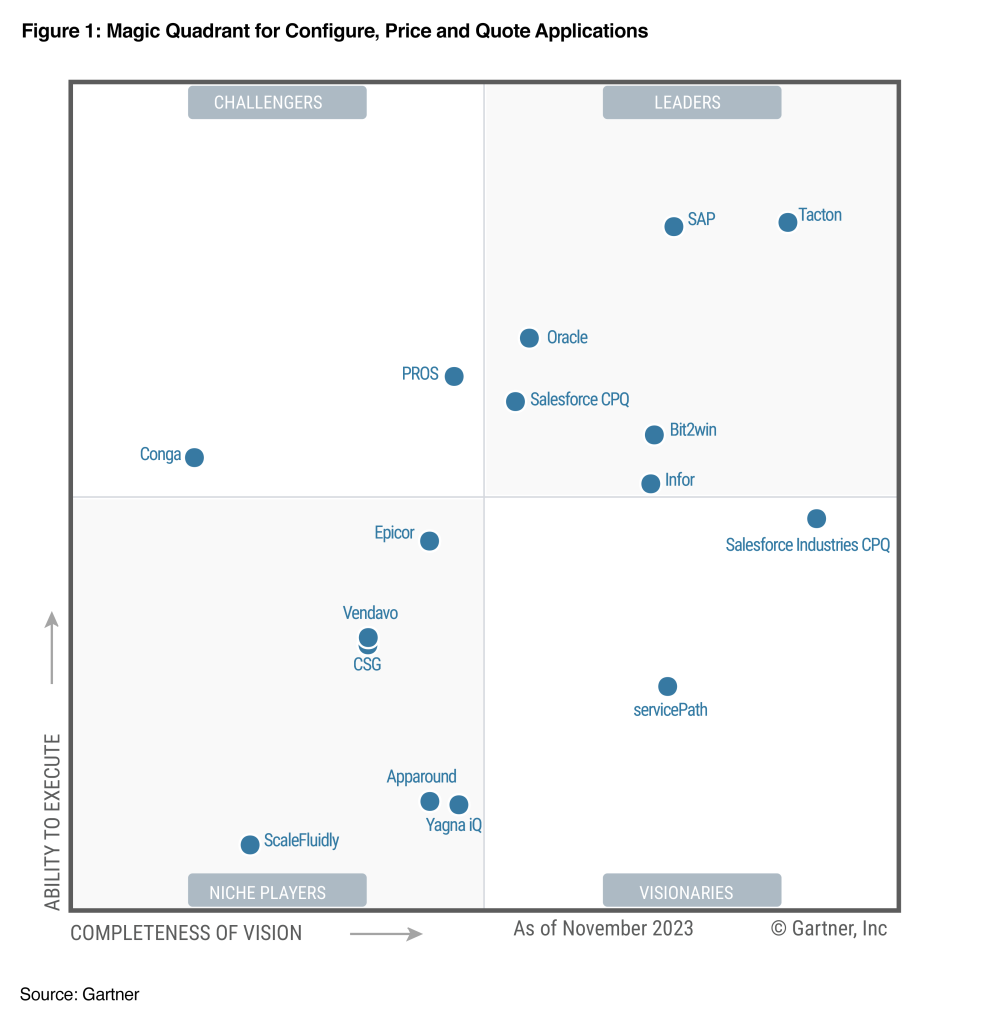

Why Now is the Time to Invest in CPQ:

Amidst technological advancements, market dynamics, and strategic imperatives, the urgency to adopt CPQ solutions has never been greater. With Tacton’s proven track record, industry expertise, and sector-specific solutions, manufacturers can overcome their pain points and embark on a journey towards operational excellence and sustainable growth.

Ready to learn more about how CPQ is changing manufacturing? Get in contact with us!